SOFTGEL MACHINE (4 IN 1)

Elevate the product to the high quality

- Gelatin & Products

- SOFTGEL MACHINE (4 IN 1)

GELATIN

FISH GELATIN

SPECIAL GELATIN

VEGETABLE GEL

V CAPSULE

SOFTGEL

MACHINE (4 IN 1)

LEAF GELATIN

4 IN 1 Soft capsule (softgel) machine

With more than 10 years of experience in helping Soft capsule customers succeed in their business, HALAMIX meets the experts with up to 4 Soft capsule Computing Challenges on board for sure.

1. Soft capsule from bovine gelatin

2. Soft capsule from fish gelatin

3. Soft capsule from powder (cassava)

4. Chewable plant-based soft capsule

Soft capsules are sealed capsules that can contain oil groups inside. The gel-strengthened shell and glycerol to contain the zombies in the capsule help it and what follows. Soft capsule calculations are essential especially for augmentation gains in the pharmaceutical industry. A supplement to your needs we ask you to take advantage of this opportunity to skyrocket your business. In the case that HALAMIX will support your business 100% by itself, all soft capsule production equipment and soft capsule production support consultants include a service that helps send your business. reach quality goals.

Halamix has 3 variants of soft capsule machines available as follows:

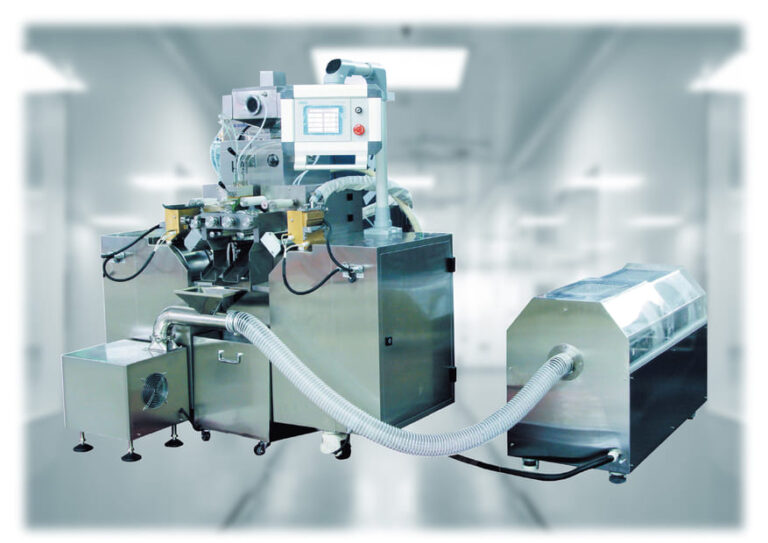

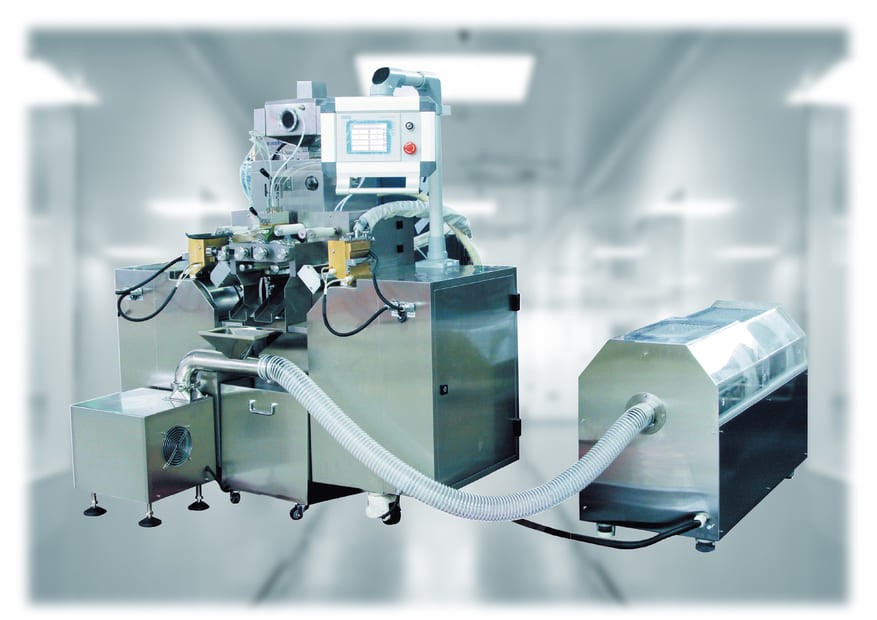

MJW200-ll series , 4 in 1 soft gel Encapsulation machine.

MJW200-ll soft gelatin encapsulation machine is elaborately designed on the base of old MJW200-ll and according to the requirements of GMP standard. It is a simple and efficient laboratory machine mainly for R&D or small batch production of gelatin capsule product in laboratories or pharmaceutical researching institutes.

The whole set of equipment is simple and efficient with small occupation. It includes a main machine, control system, water-cooling system, lubrication oil saving system, a dryer, a set of mould, as well as an auxiliary gelatin dissolving unit. All the materials for the whole set of the equipment are well selected to meet the GMP requirements, making it applicable for medical, food and cosmetic industries.

| Machine information/details | MJW200-II |

|---|---|

| Rotation Speed | 0 - 5 rpm |

| Die Roller Dimension | Ø 80 x 100 mm |

| Production Capacity (size: 8#OV) | 22,800 pcs/h |

| Production Capacity (size: 20#OB) | 8,640 pcs/h |

| Tumbler Dimension | 350 X 560 mm |

| Main Power Supply | 5 kW |

| Power | 380V / 220V, 50Hz |

| Overall Size | 1,520 X 660 X 1,350 mm |

| Weight | 400 kg |

| Material | Stainless 304 |

| Warranty | 1 year |

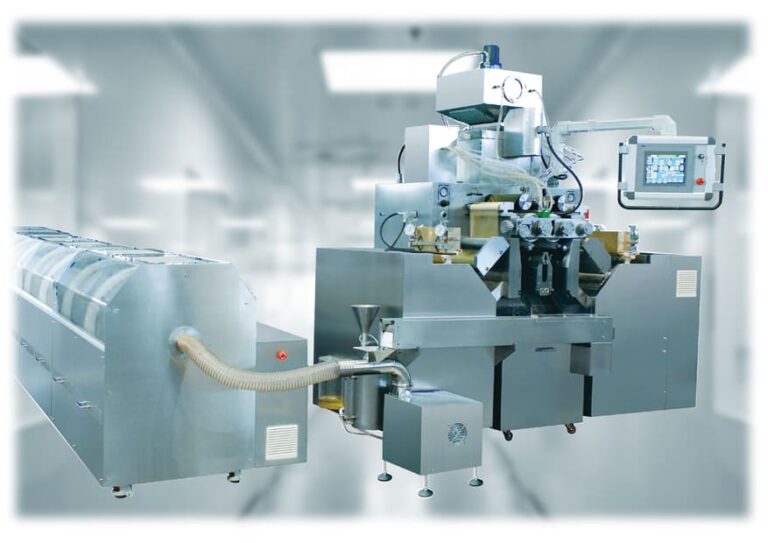

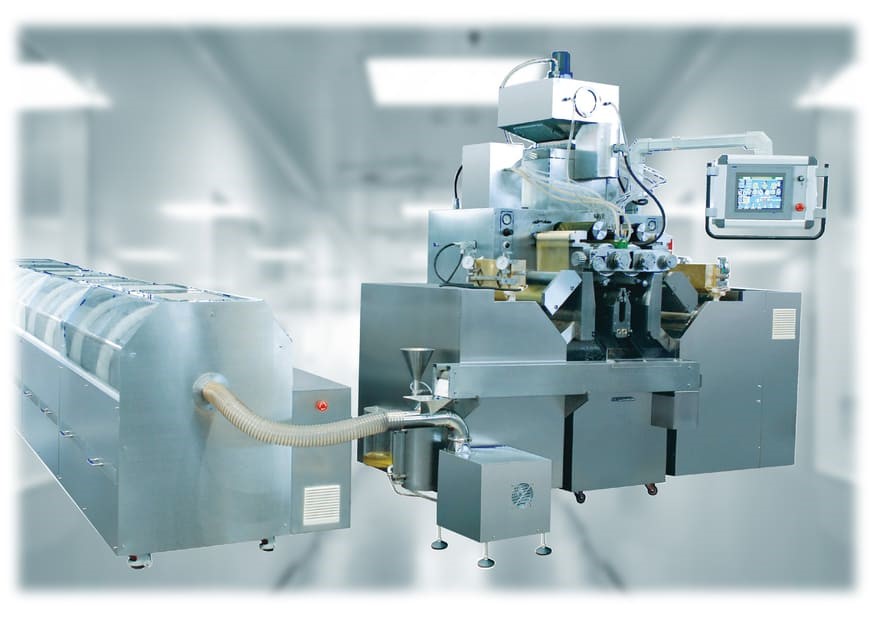

MJW362-lll series , 4 in 1 fully automatic intelligent soft capsule encapsulation machine.

MJW362-lll fully automatic intelligent soft gelatin encapsulation machine is soft capsule production equipment developed by our company on the basis of the combination of our company’s soft capsule technology experiences for many years. This equipment is of advanced technology, simple and beautiful appearance, as well as stable technological performance.

Features of the machine MJW362-lll

- The main shaft left and right holes are machined by using the boring mill imported from Switzerland, so that the runout and parallelism of the left and right main shafts are up to the international advanced level.

- The conveyer belt mode is used for the outlet port, so that the soft capsules will not be piled up at the outlet port.

- Micro-quantity lubrication technology is adopted for gelatin skin lubrication, realizing the soft capsules are free from cleaning.

- The compulsory cold air is designed at two sides of soft capsule outlet areas, as a result, the net gelatin is not easy to wind around the pill dropping unit.

- PLC control is adopted for the adjustment of loading quantity; the customer can realize the adjustment of medicine loading quantity by regulating the specific weight of the feeding materials, and to make it simpler to adjust the loading quantity.

- The pill-pressing operation process is simple and reliable because the use of pneumatic clamping system.

- Electric-driven lifting spray unit, it can stop at any position according to needs, so as to reduce the worker’s labor intensity.

- The rotating speeds of each gelatin skin roller and the main shaft are synchronous, as a result, the operation is simple instead of complicated adjustment of synchronization during operation.

- Optimized design of driving system reduces greatly the noise of whole equipment.

- The automatic measurement and control system for rubber thickness is applied to provide customer required rubber thickness and enter into the touch screen. Therefore, the rubber control system can automatically adjust the rubber to required thickness, which has greatly shortened rubber adjustment time and reduced waste of glue solution and labor strength of operators.

- The injector is heated by water-bathing, which makes the temperature of it more even and improves the capsule seam absolutely.

- The hooper is designed to keep the temperature. Therefore, it is easier to press the soft capsules with mixed and suspension liquid and automatic technology is adopted for feeding.

- Cylindrical spout design makes the forming of suspension liquid soft capsule more beautiful.

- The PLC and touch screen from the German Siemens Company is adopted for the electronic control system. The PLC and touch screen from the German Siemens Company is adopted for the electronic control system. All frequency converts from German Siemens are used; all relays from French Schneider are used; all plug-socket components form German Weidmuller are used. Therefore the electronic control system is more stable and durable.

| Machine information/details | MJW362-III |

|---|---|

| Rotation Speed | 0 - 5 rpm |

| Die Roller Dimension | Ø 150 x 250 mm |

| Production Capacity (size: 8#OV) | 120,960 pcs/h |

| Production Capacity (size: 20#OB) | 58,800 pcs/h |

| Tumbler Dimension | 600 X 900 mm |

| Main Power Supply | 12 kW |

| Power | 380V, 50Hz |

| Overall Size | 2,040 X 960 X 1,900 mm |

| Weight | 1,200 kg |

| Material | Stainless 304 |

| Warranty | 1 year |

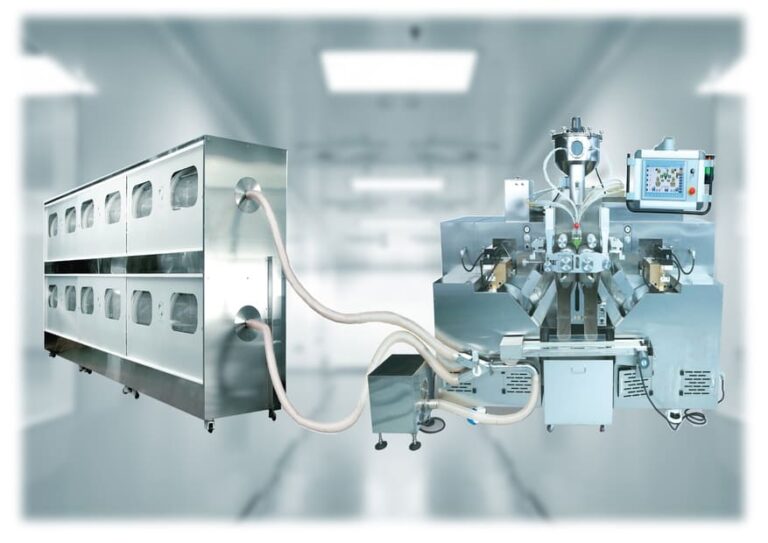

MJW362-lllA series, 4 in 1 Automatic high-speed servo soft capsule encapsulation machine

MJW362-lllA is integrated with newest encapsulation and engineering technology with our soft capsule encapsulation experience. The machine is largest production capacity in the world, die roller steady running speed up to 8 rpm. Servo motor driving and Germany mechanical parts is adopted on the machine, keep the machine running in lower noise and steady running. The machine is suit to big scales production. and the machine is in lower using cost and reduce the time and cost for maintained.

Features of the machine MJW362-lllA

- Advanced servo motor control technology was applied to increase the outlet angular speed to 8 rev/min and to reduce the transmission and vibration of the engine.

- The injector is heating by water-bathing (not heating tube), which keeps the temperature of the injector more uniform, improves the capsule seam absolutely, and reduces the problem of uneven capsule ends.

- Left and right main shaft moulds use aligning-free design. If needed, the line can be adjusted by pressing one-touch aligning button.

- The injection pump apply electrically controlled gear and the main moulds shaft to achieve synchoronous. Therefore, when changing moulds, the gears of moulds do not need to be changed as the old soft capsule machine.

- Medicine loading time and quantity can be adjusted automatically using touch screen during operation, which save more time and labor.

- The program has build-in recipe saving function, so the operation data of different products can be accessed and called as needed.

- The main shaft left and right holes are machined by using the boring mill imported from Switzerland, so that the runout and parallelism of the left and right main shafts are up to the international advanced level.

- Gelatin film lubrication adopt micro-lubricant technology to reach cleaning-free of soft capsule.

- The compulsory cold air is designed at two sides of soft capsule outlet area. Thus, the net gelatin is hard to wind around the pill dropping unit.

- The pill-pressing operation process is simple and reliable due to the use of pneumatic clamping system.

- Electric-driven lifting spray unit can stop at any position as needed to reduce the labor intensity of workers.

- Synchronism system design is applied, which greatly reduces the noise of whole equipment.

- The automatic measurement and control system for rubber thickness is applied to provide customer required rubber thickness and enter into the touch screen. Therefore, the rubber control system can automatically adjust the rubber to required thickness, which has greatly shortened rubber adjustment time and reduced waste of glue solution and labor strength of operators.

- Patented hydro-cooling technique is applied to cool the gelatin film, which avoid dew condensation problem that the formation of soft capsule on running pulley under high temperature and high humidity environment.

- The PLC and touch screen from the German Siemens Company is adopted for the electronic control system. All frequency converters are from German Siemen; all relays are from French Schneider; all plug-socket components are from italian Weidmuller. Therefore, the electronic control system is more stable and durable.

| Machine information/details | MJW362-lllA |

|---|---|

| Rotation Speed | maximum 8rpm |

| Die Roller Dimension | Ø 150 x 250 mm |

| Production Capacity (size: 8#OV) | 181,440 pcs/h |

| Production Capacity (size: 20#OB) | 88,200 pcs/h |

| Tumbler Dimension | 600 X 900 mm |

| Main Power Supply | 12 kW |

| Power | 380V, 50Hz |

| Overall Size | 2,400 X 1,260 X 2,030 mm |

| Weight | 1,500 kg |

| Material | Stainless 304 |

| Warranty | 1 year |

Starch softgels trial production guidance with gelatin machine

FAQ Guide

1. What are Softgel Capsulesn?

Softgel capsules are translucent capsules with oil filling inside, enclosed in a sealed seal of a gelatin shell.

You will use a softgel encapsulation machine to produce softgel capsules. Softgel capsules are generally popular and used by many people for the following reasons:

- You can easily customize your own softgel capsules to suit your personal shape and size.

- It has increased absorption

- You can fill different types of liquids, semi-liquids and suspensions.

- Soft gel capsules can be easily swallowed without water.

- Soft gel capsules have a tight seal that is not easy to tamper with. thus making it safer

2. How does the Softgel encapsulation machine work ?

In Softgel Encapsulation Machine Applications You will need to know how the machine works. Here is a step-by-step guide on how a softgel encapsulation machine works.

Step One: Preparing Gelatin

- First, you will prepare the outer shell of the soft gelatin capsule using ingredients such as gelatin.

- Before you start making gelatin capsules You must ensure that the softgel encapsulation machine works well.

- In this case, you will mix all the ingredients such as gelatin, plasticizer, clouding agent, water and coloring agent in a bucket.

- You will heat and mix all the ingredients in a mixing tank and dissolve the gelatin for about three hours.

- It leads to the formation of a thick syrup for the outer shell of the softgel capsule.

The second step: the formation of the filling material inside.

- This is the step where you will prepare the materials that you will fill into the soft gelatin capsules.

- The fill material is always in the form of a liquid, suspension or semi-liquid formulation.

- You may also use certain ingredients such as oils or other pharmaceutical ingredients.

- with material in hand, You will pour it into material or medicine bins.

Step Three: Soft Gelatin Capsule Encapsulation Process

- As soon as the gelatin moves from the melting tank to the distribution box The gelatin spreads in a thin layer.

- The thin layer cools and remains at a specific temperature to form the gelatin ribbon.

- It then moves from the distribution box to the tooling system corresponding to the filling material.

- at that point The ribbon wraps the filling material inside and seals it tightly to form a capsule.

- with compression The rotational molding system seals the soft gelatin ribbon with fill material inside.

- All soft gelatin capsules exit the system via a drain.

Step Four: Further Processing

- Further processing involves drying, polishing and filling of soft gelatin capsules.

- First, you will remove the gelatin capsule from the web using a peel-off roller.

- In case the gelatin capsule gets stuck You will remove it using a roll brush.

- They are moved on a conveyor belt to the drying unit.

- You will place soft gelatin capsules on a tray and transfer them to a tumble dryer.

- You’ll leave it under the dryer for a while to remove excess moisture from the capsules.

- Then put it in a polishing machine to polish thoroughly.

- Finally, you will inspect the soft gelatin capsules and dispose of any defective softgels before packaging.

3. What is the quality standard for Softgel encapsulation equipment ?

When you buy soft gelatin encapsulation machine You must ensure that the quality standards you set are met.

Here are the main quality standards you need to confirm about your soft gelatin encapsulation machine.

- Current Good Manufacturing Practices (cGMP) quality standards.

- CE quality standards for electrical systems and on-board units.

- International Organization for Standardization (ISO) quality standards

- FDA FDA for the safety of the machine and capsules.

4. What is the specification of Softgel encapsulation machine ?

You must consider the specifications of the soft gelatin encapsulation machine when selecting the encapsulation machine. Here are some specs you need to look at.

Size : This is related to the size of the softgel encapsulation machine in terms of length, width, height as well as weight. You will need to find the right size for the soft gelatin encapsulation machine to meet your specifications.

Electrical requirements : Your electrical requirements will depend on the type of machine you use. The larger the machine, the higher the consumption rate according to the production rate. Fully automatic softgel encapsulation machines are also energy intensive compared to semi-automatic softgel encapsulation machines.

Wind requirements : In this case, you will look at the pressure requirements of the softgel encapsulation machine. Depending on the workload, you specify how much pressure the machine needs.

Material : The best material for making a soft gelatin encapsulates is stainless steel. Stainless steel is stronger, more durable and hygienic as it is easier to sterilize. In addition to stainless steel, there are non-stainless steel parts and you may also find materials such as rubber.

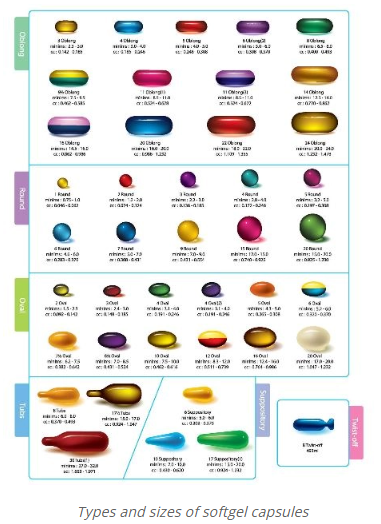

5. What shapes and sizes are available for Softgel encapsulation machines ?

You will use a softgel encapsulation machine to create softgel capsules of various shapes and sizes. Here you will need to change the tooling system to achieve different shapes and sizes.

Some of the shapes that you can make using the softgel encapsulation machine are:

- Oblong, Round, Tube, Oval, Other shape like star, heart softgel Capsules

The sizing of the softgel capsules also vary from 000 which is the biggest to size 5 which is the smallest.

6. What factors affect the efficiency of the softgel encapsulation process ?

The softgel encapsulation process comes with standard machines that you can modify to increase production efficiency. The machine has automatic sensors that will alert you when every production step has been completed. It also helps you in setting different levels. And know when to make specific adjustments on the production line. Integrating all systems and machines into one production line will make the production line more efficient.

In addition to the above factors You should consider the following:

- Softgel encapsulation machine speed : This will determine the capacity of your production process.The higher the speed of your machine. The higher the production capacity and efficiency.

- The quality of the softgel encapsulation machine : The better the quality of the softgel encapsulation machine. The more efficient the encapsulation process is.

- Versatility of the Softgel Encapsulation Machine : You must ensure that you have the right equipment that performs the necessary functions in the softgel encapsulation process. It would be better if you consider including accessories to increase efficiency.

- Softgel encapsulation machine drying process : You should consider the options. in the drying process according to the type of softgel capsules you produce.For example, when you manufacture oil-based softgel capsules, You may consider using an in-line drying system for best results.

- Employee provisioning : You should consider educating your employees the best for softgel capsule manufacturing. in that case They will be more efficient in managing machines and products.

- Gelatin formula : You should make sure that you get all the ingredients and the right size to make your gelatin recipe.

- Process Assessment : You should more accurately assess the manufacturing process on a regular basis to ensure that the machines are in good working order.

7. How does a softgel encapsulation machine control the quality of capsules?

You can control the quality of softgel capsules by using different softgel encapsulation equipment.

Here’s how you can control the quality of the capsules.

- Using high-quality machines that are more reliable and efficient.

- Mix all the right ingredients to make the right potion to ensure high quality softgel capsules.

- Ensure that the equipment you purchase meets international quality standards.

- Using different types of support equipment such as:

- Softgel capsule inspection machine to check the quality of softgel capsules.

- Softgel sorting machine to sort them into different grades.

- Softgel scrubber to clean and remove debris from capsules.

8. Is it possible to control the mold synchronization of the softgel encapsulation machine ?

- It is possible to control the mold synchronization of the softgel encapsulation machine for a consistent and consistent softgel capsule.

- You can control the die synchronization of the softgel encapsulation machine by adjusting and modifying the mechanical encapsulation gadget.

- In case of deviation in tool system alignment You will receive appropriate notifications on the dashboard.

- Without proper alignment There is a high chance of producing softgel capsules with irregular shapes and sizes.

- You should consider the mold synchronization control of the machine to avoid capsule leakage.

- You should also consider having an automated mold synchronization system that will guarantee efficiency while minimizing downtime.

9. What should you consider when purchasing Softgel encapsulation equipment ?

- When purchasing a Softgel Encapsulation Machine You should look at the technical specifications.

Here are some factors you should keep in mind:

- Machine price

- You should consider buying a handset that falls within your budget.

- This includes considering the cost of purchasing, operating and maintaining your machine.

- Automation level

- Since most of the softgel encapsulation machines are automatic. So you should consider buying one with the latest technology.

- It may cost you more. But the return on investment will also be high.

- Size of the machine

- You should purchase a softgel encapsulation machine that is suitable for the size of your production facility.

- This includes all dimensions in terms of height, length, width and even weight of the machine.